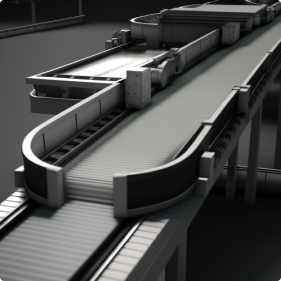

Fabric Rubber Conveyor Belt

Heat Resistant

Conveyor Belt

Belts that are engineered for tough conditions

Reliable, efficient, and heat-resistant our conveyor belts have it all.

Heat Resistant Conveyor Belt

Tensile

Strength

100-6000 N/mm

Belt Width

300-2400mm

Suitable

Operations

Hot sintered ore, Hot pellet,

hot clinker, hot chemical,

fertilizer, hot cement etc.

Fabricated from premium quality rubber, we manufacture Heat

Resistant Conveyor Belts that not only assure high quality, but

also are well suited for heat resistance applications. These are

suitable for critical operations like hot sintered ore, hot

pellet, hot clinker, hot chemical, fertilizer, hot cement etc.

The life of these belts depends on the construction of belt and

temperature of conveyed materials. Apart from this, speed of

conveyor, wear properties of materials, any chemical actions and

size of materials also affect the life of these conveyor belts.

Heat resistant conveyor belt is available in three different types of carcass namely, steel

cord, nylon and polyester. With tensile strength varying between

100 – 6.000N/mm and belt width within 300 – 2400mm, steel cord

belts are available in 50m and over, while fabric belts are

available in only 10m and over.

HOW TO SELECT THE RIGHT BELT

Wondering which would be the

right heat resistant belt ?

Surface temperature of the belt varies with the type and size of the material being carried. Like large lumps (sintered ores, coke), which allow air to circulate, the belt surface would be cooler than the lumps.

In case of powdery or similar materials such as cement, alumina, carbon black etc. there is almost no temperature difference between material and belt surface. Therefore, while selecting a belt, it is necessary to know not only the temperature of the material to be carried, but also to have an accurate idea of the surface temperature (the belt will be operating at).

Types

T1, T2, T3

Rubber cover in this type of belt is available in three types, T1,

T2 and T3. The low temperature T1 rubber cover allows temperature

range on materials within 70° – 150° or 200°C, while the belt

surface temperature ranges between 60° - 120°C. With its heat

hardening type feature, this rubber cover is suitable for low or

medium temperature materials which are abrasive like coke,

sintered products etc.

T2 and T3 are allow temperature range of materials within 100° -

200° or 250°C. T2 is heat softening type, possesses almost non

crack cover and is suitable for hot powdery materials and high

temperature materials which are medium abrasive like sintered ore

products, cement clinker etc.

T3 is excellent wear resistant cover under high temperature and is

suitable for lumpy materials or high temperature materials which

are very abrasive like coke, sintered ore products etc.

FOR THE USER

Anything I need to

know more about this belt?

Temperature of the material being transported and the belt’s surface temperature vary according to the material and shape. For instance, when materials have a temperature of 150°C (such as coke or sintered ore) and have a relatively small contact area, belt’s surface temperature could remain at 60° - 80°C. In contrast, when powdered material like cement is being conveyed, the material and belt surface temperature do not differ so greatly. The lifetime of the heat resistant belt is largely affected by the belt’s surface temperature during operation.

CHARACTERISTICS OF THE BELT

Well, there are more

features than you think.

Rubber cover and carcass should not deteriorate due to heat.

Rubber cover on carcass should maintain excellent properties,

even at high temperatures and good adhesion to form one unit,

even when they are exposed to high temperatures.

The surface temperature of heat resistant belt varies with the

material type, belt speed, loading rate and size depending on

circumstances. In order to select the proper heat resistant

belt, it is necessary to consider not only the temperature of

the material to be conveyed, but also the surface temperature

of the belt.

RESTRICTIONS OF THE BELT

Things you need to care

about while using the belt

SBR heat resistant belt should not be used when:

Powdered material is over 70°C.

Strong acid or alkaline is used

Oil products and oil-stained substances are used.

The operation site or the materials require flame-resistant belts

EPDM Heat Resistant Belt

EPDM heat resistant belts should not be used when:

Powdered material is over 180°C

Oil products and oil-stain other than vegetable oil are present.

Location of the materials requires flame resistant belts.

OUR PRODUCTS

Explore Our Products

Rare Earth Conveyors Pvt Ltd.

Let us help you move forward – contact us now to explore our range of high-performance conveyor belts!

+91-124-3537091

customer.support04@rareearth.in

1.png)